The Versatility and Importance of Membrane Rubber in Modern Industry

The world of manufacturing and production is ever-evolving. Among the many materials that have played crucial roles in industrial processes, membrane rubber stands out due to its unique properties and diverse applications. Whether used in vacuum systems, manufacturing processes, or as a component in various devices, membrane rubber enhances efficiency and durability. This article explores the myriad benefits and applications of membrane rubber, aiming to provide insights into its pivotal contribution across various industries.

Understanding Membrane Rubber

Membrane rubber is a specialized material designed to function as a barrier, providing a responsive surface that can deform under pressure and return to its original shape. This elasticity is what makes membrane rubber ideal for applications requiring durability and flexibility.

Characteristics of Membrane Rubber

- Elasticity: Membrane rubber can stretch and flex while retaining its original shape, making it an ideal choice for applications involving repetitive motion.

- Resistance to Chemicals: It can withstand exposure to various chemicals, oils, and solvents, which is crucial for industries like automotive and manufacturing.

- Temperature Resilience: Membrane rubber can operate effectively in a wide range of temperatures, ensuring reliability in extreme conditions.

- Weather Resistance: Its ability to resist UV radiation and ozone degradation makes it suitable for outdoor and harsh environmental applications.

Applications of Membrane Rubber

Due to its remarkable properties, membrane rubber has a plethora of applications across different sectors. Here are some of the key areas where it is utilized:

1. Vacuum Systems

Membrane rubber is integral to vacuum systems, where it acts as a sealing component. Its ability to maintain a tight seal under varying pressures makes it indispensable in these contexts. In vacuum presses, for instance, high-quality membranes ensure that air is effectively removed from the chamber, leading to optimal performance. The consistent performance of membrane rubber in vacuum systems lower operational costs and improve product quality.

2. Manufacturing Processes

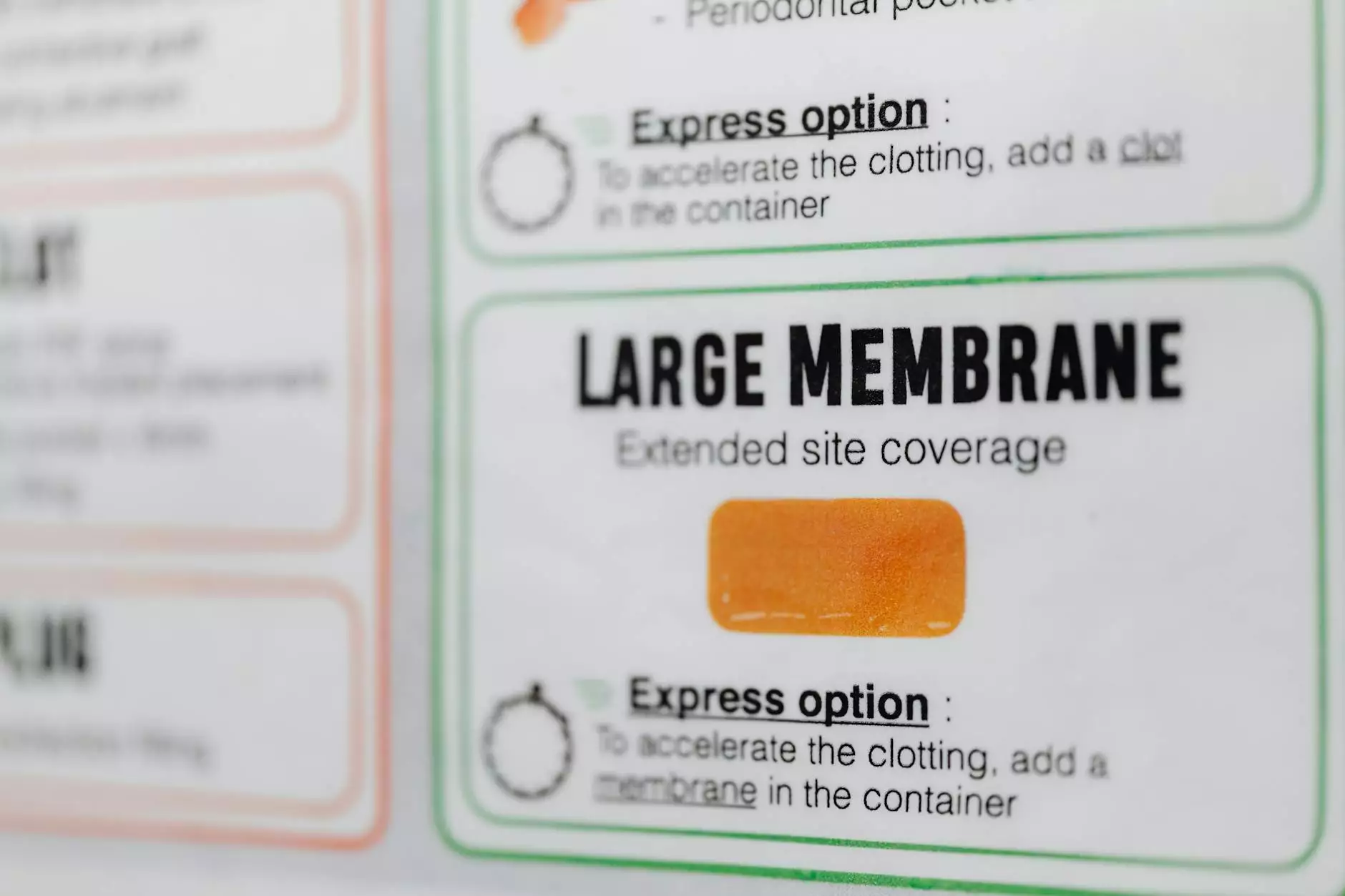

In manufacturing, particularly in molding processes, membrane rubber is often utilized as a forming medium. It allows for the precise shaping of components while providing a reliable barrier against contaminants. For example, in the production of silicone membranes and other synthetic products, membrane rubber plays a crucial role in ensuring that the final product meets stringent quality standards.

3. Natural Rubber Membranes

Natural rubber membranes offer unique properties that synthetic options may not provide. They are biodegradable and exhibit excellent tensile strength and flexibility. Many industries are now turning to natural rubber membranes to create environmentally friendly solutions without sacrificing performance. This transition aligns with the growing demand for sustainable practices in manufacturing.

4. Automotive Industry

The automotive industry heavily relies on membrane rubber for various applications, from sealing components to providing damping solutions. The resilience and durability of membrane rubber ensure that automotive parts can withstand harsh conditions, including extreme temperatures and exposure to oils. This reliability translates to enhanced safety and performance for vehicles.

5. Medical Applications

In the medical field, membrane rubber is used in manufacturing components for devices such as syringes, blood bags, and various diagnostic equipment. Its ability to maintain sterility and resist chemical exposure ensures that medical devices function effectively while adhering to stringent health regulations. As the medical industry continues to innovate, the demand for high-quality membrane rubber will only increase.

Benefits of Using Membrane Rubber

The adoption of membrane rubber across various industries is propelled by its extensive benefits. Here are some of the key advantages:

1. Enhanced Product Quality

With its unique properties, membrane rubber helps improve the overall quality of products. In processes like vacuum molding, using high-quality membrane rubber ensures that the final product is free from defects and has a smooth finish.

2. Cost Efficiency

Investing in membrane rubber can significantly reduce operational costs. Its durability means fewer replacements, and its effectiveness in vacuum systems enhances energy efficiency, reducing energy consumption and costs over time.

3. Customization and Flexibility

Membrane rubber can be tailored to meet specific needs, from thickness to composition. This customization allows businesses to optimize their processes according to their unique requirements, leading to greater flexibility in production.

4. Environmental Sustainability

With increasing awareness of environmental issues, the use of natural rubber membranes promotes sustainability. These materials are biodegradable and can help companies reduce their carbon footprint while still meeting performance standards.

Choosing the Right Membrane Rubber for Your Needs

When selecting membrane rubber for your applications, consider the following factors:

- Compatibility: Ensure that the membrane rubber is compatible with the chemicals and temperatures it will be exposed to.

- Thickness: The thickness of the material can affect its performance. Choose a thickness that caters to the specific pressures and conditions of your application.

- Supplier Reputation: Source your membrane rubber from reputable suppliers who guarantee quality and reliability.

- Customization Options: Look for suppliers who offer customized solutions tailored to your specific application needs.

Conclusion

In conclusion, membrane rubber is a vital component in modern industrial applications across various sectors, including manufacturing, automotive, and medical fields. Its unique properties, ranging from flexibility and chemical resistance to environmental sustainability, make it a superior choice for addressing the challenges of today’s manufacturing demands. As industries continue to innovate, the reliance on high-quality membrane rubber will undoubtedly grow, leading to enhanced efficiency, product quality, and sustainability. For businesses looking to improve their operations and product reliability, investing in high-grade membrane rubber is an essential step toward achieving operational excellence.

Explore Our Range of Membrane Rubber Products

If you are interested in investing in high-quality membrane rubber solutions, check out our extensive range of products at vacuum-presses.com. We offer a selection of membranes, including silicone membranes, rubber membranes, and natural rubber options, designed to meet your specific needs. Contact us today to learn more about how our membrane rubber products can enhance your operations and drive success.